Scientists are closer to giving the next generation of solar cells a powerful boost by integrating a process called singlet fission.

In a study published in Nature Chemistry, researchers unravel the scientific understanding of what happens when light particles split—a process called singlet fission—and its underlying workings.

Lead researcher Professor Tim Schmidt from UNSW Sydney’s School of Chemistry has studied singlet fission for more than a decade. He says the process could be invoked and applied to improve existing silicon solar cell technologies.

“Today’s solar cells work by absorbing photons which are then sucked away to the electrodes to do the work,” Prof Schmidt says.

“But as part of this process, a lot of this light is lost as heat. Which is why solar panels don’t run at full efficiency.”

Related article: Research breakthrough could lead to ‘self-healing’ solar cells

Pushing the limits

Almost all photovoltaic solar panels on the market today are made from silicon. Co-author Professor Ned Ekins-Daukes from UNSW’s School of Photovoltaics & Renewable Energy Engineering says although the technology is now cheap, it is also nearing its fundamental limits in terms of performance.

“The efficiency of a solar panel represents the fraction of energy supplied by the sun that can be converted into electricity,” Prof Ekins-Daukes says.

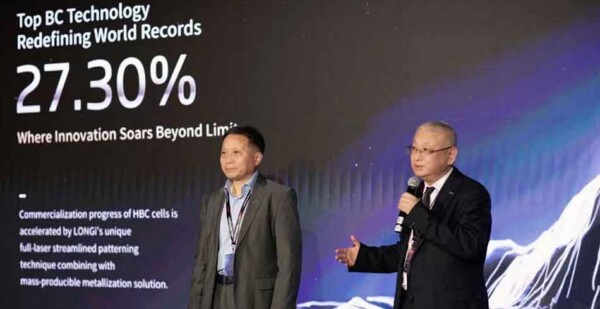

“The highest efficiency was set earlier this year by our industrial collaborator, LONGi. They demonstrated a 27.3% efficient silicon solar cell. The absolute limit is 29.4%,” he says.

Prof Schmidt says scientists are still trying to understand how the molecular process of singlet fission worked. Specifically, how does one become two? He says the process is complex and detailed.

“Our study addresses the route of this process. And we used magnetic fields for the interrogation. The magnetic fields manipulate the wavelengths of emitted light to reveal the way that singlet fission occurs. And that hasn’t been done before.”

Working smarter, not harder

Different colours of light have photons with different energies. Prof Schmidt says it doesn’t matter what the incoming energy of the light is—it will always supply the same energy to the cell, and any excess energy gets turned into heat.

“So, if you absorb a red photon then there’s a bit of heat,” he explains.

“With blue photons, there’s lots of heat. There is a limit on efficiency for solar cells.”

He says a paradigm shift is needed to allow silicon cells to achieve a greater potential.

“Introducing singlet fission into a silicon solar panel will increase its efficiency,” Prof Ekins-Daukes says.

“This enables a molecular layer to supply additional current to the panel.”

The process breaks the photon into two smaller energy chunks. These can then be used individually. This ensures more of the higher energy part of the spectrum is being used—not lost as heat.

Related article: CSIRO achieves record efficiency for printed solar cells

Investing in the future

Last year, the Australian Renewable Energy Agency (ARENA) selected UNSW’s singlet fission project for their Ultra Low Cost Solar program. The program aims to develop technologies capable of achieving greater than 30 per cent efficiency at a cost below 30 cents per watt by 2030.

The team used a single wavelength laser to excite the singlet fission material. Then they used an electromagnet to apply magnetic fields—which reduced the speed of the singlet fission process, making it easier to observe.

“From this firm scientific understanding of singlet fission, we can now make a prototype of an improved silicon solar cell and then work with our industrial partners to commercialise the technology,” Prof Ekins-Daukes says.

“We’re confident we can get silicon solar cells to an efficiency above 30%,” Prof Schmidt says.